Access high-performance spray foam and integrated roof systems in Odessa that regulate heat, air, and moisture in one assembly per IECC/IRC and IBC. Choose open-cell to optimize vented attics and sound control, or closed-cell to achieve higher R-value, Class II vapor control, and rigidity. We air-seal per IECC R402.4 and confirm with blower-door testing. UV-rated coatings protect SPF per ASTM and CRRC. Professional installation follow OSHA and IRC R316. Continue reading to discover choices, value, and guarantee specifics.

Key Takeaways

- SPF excels in Permian Basin extreme conditions, effectively controlling heat, air, and moisture while satisfying IECC/IRC standards for air-sealing and vapor-control.

- Open-cell insulation provides ventilation to wall cavities and attic areas, while closed-cell offers higher R-value, increased structural integrity, and acts as a Class II vapor retarder when applied to code thickness.

- Continuous SPF roofs with sun-blocking coatings decrease leaks, boost reflectance, and meet building code standards.

- Our specialists maintain OSHA safety guidelines and establish appropriate containment processes, performing test shots, managing safety controls, and validating application thickness and air sealing through detailed blower-door analysis.

- Look forward to lower HVAC runtime and three to seven year cost recovery; verified ACH50, R-values, and warranties support code compliance and rebates.

Understanding Spray Foam's Effectiveness in the Permian Basin

Although West Texas undergoes temperature swings from triple-digit summers to cold snaps and dust-laden winds, spray polyurethane foam (SPF) performs consistently because it controls heat, air, and moisture in an integrated assembly. You achieve heat protection from a seamless, air-impermeable layer that limits heat transfer and airflow gains per IECC and IRC N1102/IECC R402 air-sealing criteria. SPF also decreases moisture migration by preserving warm-side temperatures above dew point, meeting IRC R701.3 vapor control intent and IBC 1403 weather protection.

Open-Cell or Closed-Cell: Selecting the Ideal Foam

Prior to picking a foam type, match its specifications to your building requirements, regulations, and cost considerations. ocSPF delivers superior vapor diffusion and noise reduction, well-suited for interior walls and ventilated attics. It generally offers thermal resistance of R-3.6 to R-4 per inch, so calculate depth to meet IECC/IRC R-values. ccSPF provides higher R-6 to R-7 per inch, structural strength, and exceptional air sealing that reduces thermal bridging. In West Texas's mixed-dry climate, ccSPF can serve as a Class II vapor retarder at one and a half to two inches; check dew-point control per IRC R702.7 and wall and roof assemblies.

You must handle thermal and ignition barriers per IRC R316 and manufacturer ESR reports. Verify moisture levels meet specifications, provide adequate ventilation throughout the installation process, and use PPE to mitigate isocyanate exposure.

Advanced Roof Coatings for Superior Protection

You have the option to install a seamless, monolithic membrane that removes joints and penetrating hardware, decreasing the chance of leaks and complying with IBC performance standards for roof coverings. With ultraviolet-protective coatings (e.g., acrylic, silicone, or polyurethane), you safeguard SPF from UV degradation and ensure reflectance per Energy Star and CRRC specifications where applicable. Adhere to manufacturer data sheets, ASTM classifications D6083/D6694, and OSHA fall-protection requirements during installation for code-compliant, secure implementation.

Monolithic Membrane Benefits

As soon as a roof coating cures into a monolithic membrane, it gets rid of seams-the weakest link in most assemblies-and creates a uninterrupted, watertight barrier that stands up to wind-driven rain and standing water. You get monolithic durability that limits capillary intrusion at junctions, fasteners, and penetrations. By eliminating lap website joints, you reduce failure points and fulfill IBC Section 1507 performance intent for roof coverings and IECC air-control objectives through continuous insulation continuity.

Such a monolithic structure increases wind resistance when installed according to FM Global approvals and ANSI/SPRI standards, preserving attachment integrity throughout Odessa's wind events. This approach streamlines maintenance, because inspections focus on individual damage points as opposed to miles of seams. Be sure to require correct base preparation, moisture testing, and wet-mil verification to achieve designed dry-film thickness, adhesion, and secure, code-compliant performance.

UV-Protected Waterproofing Systems

To ensure a monolithic membrane's protection, it's essential to use UV-resistant waterproofing layers that won't deteriorate under Odessa's high-irradiance conditions. Opt for elastomeric topcoats formulated with UV stabilizers and reflective additives to achieve cool-roof performance specifications. Verify coatings comply with IRC/IBC energy provisions and ASHRAE 90.1 for solar reflectance and thermal emittance; review CRRC ratings to validate SRI. For spray polyurethane foam, install a compatible aliphatic polyurethane or silicone topcoat at the manufacturer's required dry film thickness, maintaining slope-to-drain.

Follow ASTM D6083 for acrylic standards, and perform field adhesion testing as per ASTM D4541. Verify substrate moisture content and ambient conditions in accordance with OSHA safety requirements and SDS. Check for pinholes, holidays, and edge terminations; fix without delay to maintain seamless, moisture-resistant integrity.

Air Sealing Solutions for Comfort and Health

While often overlooked, proper air sealing serves as a cornerstone to more wholesome, cozier buildings in Odessa's hot and gusty conditions. By controlling uncontrolled air movement per IRC N1102/IECC requirements, you decrease dust, pollen, and outdoor contaminants, protecting indoor air quality and inhabitant wellness. Spray foam insulation functions as both an air barrier and Class II vapor retarder when placed at code-specified thickness, controlling moisture-laden air movement that may cause dampness and fungal growth.

You'll additionally minimize temperature fluctuations and air leaks by reducing thermal bridging at structural transitions, top plates, and rim joist areas. Use blower-door testing (IECC R402.4) to verify airtightness targets and locate air infiltration points. Seal penetrations around HVAC components, lighting fixtures, and plumbing penetrations with appropriate fire-rated products when necessary (IRC R302). Be sure to provide ventilation per ASHRAE 62.2 for proper air exchange.

Utility Rebates, ROI, and Energy Savings

Reduce energy costs and stabilize monthly bills by targeting the primary energy inefficiencies first: the home's shell and ductwork. Both types of spray foam reduce air infiltration as per IECC standards and thoroughly seal ducts following IRC/IMC standards, leading to lower HVAC usage and peak demand. You'll experience seasonal energy savings as the insulation controls warm weather heat gain and winter heat escape, enhancing climate control.

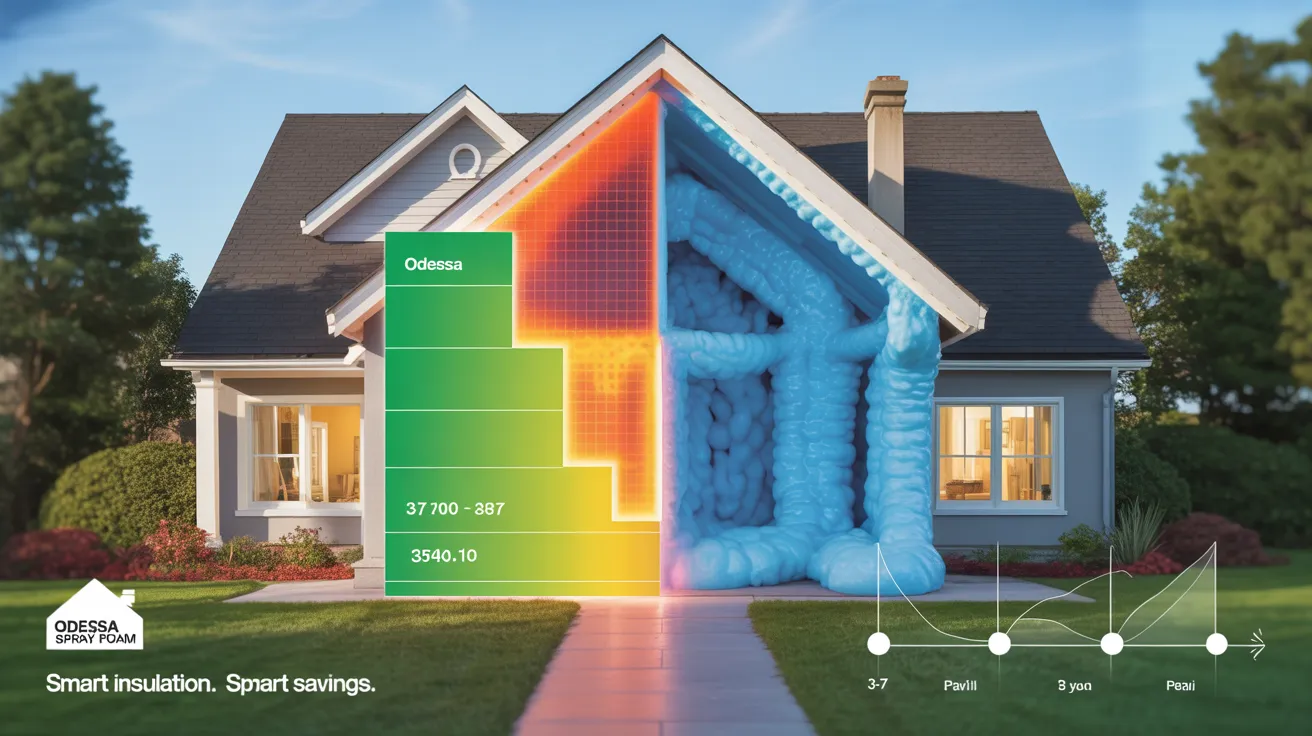

Assess ROI by pairing decreased kWh/therms with Odessa utility rates. Typical simple payback ranges 3-7 years, with continuing payback progressing as energy prices rise. Verify R-values, ACH50 results, and duct leakage to outside (CFM25) to quantify performance. Check Oncor and local co-op rebate portals for performance-based incentives, energy improvement financing, and demand-response bonuses. Document insulation certificates, combustion safety tests, and code compliance to meet eligibility.

Building Construction and Retrofit Implementation

Whether you're planning new construction or renovating an existing property, spray foam works uniquely in each case but achieves similar results: a reliable barrier for air, heat, and moisture that meets building codes. When building new, you can detail continuous insulation at the roofline and walls, ensure air and thermal barriers work together, and meet IECC/IRC R-value or U-factor trade-offs. You'll design properly insulated attics, protected rim joists, and managed air flow rather than passive foundation vents, while combining foam with moisture barriers when necessary.

When performing retrofits, you must identify and fix existing gaps, ensure substrate dryness, and carry out combustion safety with CAZ testing. You'll secure crawlspaces, seal off foundation vents according to code, and add mechanical ventilation to meet ASHRAE 62.2. Using closed-cell foam creates structural reinforcement and flood resilience; meanwhile open-cell is ideal for sound control and moisture management.

Our Installation Process and Warranty Options

Here's our comprehensive installation plan: inspection of the substrate, humidity assessment, ventilation system preparation, and spray foam installation to achieve designated R-values per IRC/IECC and manufacturer data sheets. We prepare the jobsite with isolation measures, PPE, thermal protection validation, and ventilation to fulfill OSHA/NIOSH standards and local fire-code specifications. We'll detail warranty coverage options, including material and workmanship terms, what's covered (adhesion, density, R-value), exclusions, and materials necessary for claims.

Installation Instructions

Before installing any amount of foam in your Odessa residence, we validate substrates, safety, and scope following IRC/IBC and manufacturer specifications, then explain the process and warranty terms. We check substrate temperature, adhesion, and moisture targets, document R-value goals as specified by IECC, and determine closed- or open-cell per application.

We begin by executing foam mixture preparation and equipment calibration following manufacturer guidelines. We monitor temperature and pressure readings, and perform an initial spray test to assess foam expansion and reaction. We then apply with measured applications, adhering to proper ventilation and ignition barrier specifications as outlined in IRC R316. We verify measurements with measurement tools, secure all transitions, and capture images of the installation.

Finally, we complete comprehensive cure verifications, issue a detailed workmanship guarantee, and register product warranties along with serials and batch data.

Worksite Setup and Safety

While each property is unique, our crews follow standardized jobsite prep procedures following OSHA 29 CFR 1926 and manufacturer requirements: we set up isolated work areas using poly containment, configure negative air according to ASHRAE 62.2 standards, and post access control with PPE requirements (full-face respirators, gloves, Tyvek). We utilize lockout/tagout procedures for HVAC and electrical as applicable, and we confirm make-up air to avoid combustion appliance backdrafting per IRC M1503. We place Class ABC extinguishers, examine SDS sheets, and conduct hazard communication briefings under 29 CFR 1910.1200. To ensure site safety, we protect adjacent finishes, shield ignition sources, and employ intrinsically safe lighting. We measure VOCs and isocyanate exposure, preserve egress routes, and document daily JHAs. After curing, we provide ventilation, remove containment, and complete a final safety inspection.

Coverage Options & Warranties

Though effectiveness starts with correct prep and installation, your coverage is secured through layered warranties tailored to Odessa's climate and codes. You get a material warranty from the manufacturer and a workmanship guarantee from the contractor, both conforming to IRC/IBC and IECC requirements for foam, ignition barriers, and roof assemblies. Additional warranty coverage is offered when you combine SPF with authorized coating systems and maintain yearly checkups.

The policy covers important SPF specifications like density, adhesion, R-value retention, and moisture resistance, assuming correct code-compliant ventilation and moisture control is maintained. We carefully record material moisture content, lift thickness specifications, and curing conditions to ensure coverage validity. Coverage transfer options permit coverage to transfer to subsequent property owners with documented upkeep history. Additional coverage for hail damage and UV deterioration may be included. Policy exclusions encompass misuse, unauthorized modifications, and failure to maintain.

Frequently Asked Questions

Do You Offer Financing Options or Payment Plans for Insulation Projects?

Absolutely, we offer structured payment options and flexible financing. We provide features such as deferred payments, 0% same-as-cash promos, and low-APR terms, subject to credit approval. We schedule payments according to project phases (prep, installation, final inspection) and meet code-compliant scope per IRC/IECC R-values and fire safety (NFPA 286/ASTM E84). We'll provide a transparent cost breakdown, lien documentation, and warranty terms. Submit your application online or in person; we'll pre-qualify you without impacting installation timelines.

Are Your Technicians Certified and Background-Checked for On-Site Work?

You're protected by carefully screened specialists. Picture a carefully managed worksite where every tool operates perfectly; you operate safely because each technician passes thorough criminal history checks and possesses professional certifications. They satisfy OSHA 10/30 safety requirements, comply with EPA RRP and ICC/IRC insulation regulations, and maintain NFPA 286/285 fire-testing protocols for assemblies. You receive properly identified teams, validated certifications, and leadership verification, confirming correct applications, clean clearances, and optimal results with traceable records.

When Can We Arrange Your On-Site Assessment in Odessa?

We can schedule your on-site assessment starting today, based on today's schedule, or in 24-48 hours. We also accommodate weekend assessments. You'll get a Level 1 pre-screen per IRC R316 and OSHA 29 CFR 1910.134, examining ventilation, ignition sources, and access. We'll assess substrate moisture (≤19%), ambient temp/humidity, and roof load limits. You'll be given a written scope, safety plan, and permit guidance. Contact us now to lock in your time.

Which Foam Brands and Chemical Formulations Do You Work With?

Comparable to a well-tuned engine, you'll experience consistent performance from our designated brands and formulations. You'll choose certified polyurethane blends from Huntsman/Demilec, Carlisle, and ICP. We apply closed cell chemistries (2 lb, HFO-blown, Class II vapor retarder) and open-cell systems, all ICC-ES evaluated (ESR- reports) and conforming to IRC/IBC, NFPA 286, and ASTM E84. We provide proper ignition/thermal barriers per code, manufacturer-specified lift thickness, substrate temps, and PPE-focused safety during application and cure.

Do You Manage HOA Compliance and Permit Applications?

Absolutely. You'll receive dedicated HOA liaisons to analyze CC&Rs, handle architectural review packets, and follow approvals. We manage permit management end-to-end: construction drawings, product data sheets, ICC-ES reports, and energy code compliance per IRC/IECC. We arrange inspections, maintain OSHA-compliant jobsite practices, and document NFPA 285/UL listings where applicable. You'll obtain stamped drawings if required, plus detailed specifications, ventilation plans, and disposal manifests, securing full jurisdictional compliance and a complete closeout.

Conclusion

You're not following illusions-you're crafting comfort. In Odessa's weather, SPF satisfies IECC/IRC R-values and ASHRAE 90.1 standards, while seamless roof coatings provide Title 24-grade reflectivity and ASTM D6083 resilience. You'll secure enhanced air barriers per ASTM E2178/E2357, Class A options per ASTM E84, and vapor control to IRC R702.7. We follow OSHA 1910/1926 PPE and ventilation protocols, then support implementations with documented warranties. Want to lock in cost efficiency, convenience, and code conformity-without problems or guesswork?